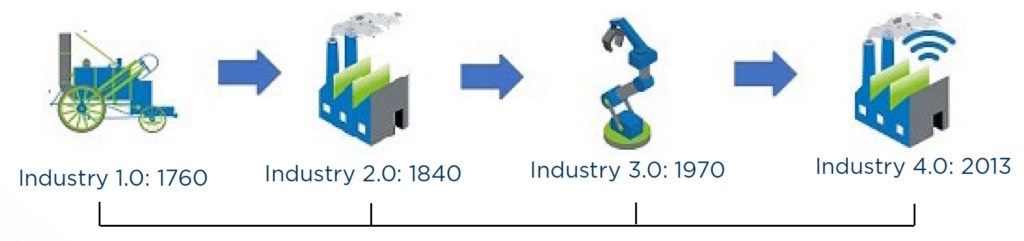

ENVEA have been at the forefront of environmental monitoring and process control over four decades and with the emergence of the industrial internet of things (Industry 4.0) ENVEA are yet again providing innovative solutions which harness the potential of this new industrial era.

At Clean Air Technology Expo taking place on 11-12 September at the NEC, Birmingham, ENVEA will be demonstrating its range of Particulate Emissions Instruments alongside its advancements in data capture, storage and analytics that will combine the world of industrial particulate and flow monitoring with the latest in smart technology.

In this series of articles, we will be exploring the relationship between industrialisation and particulates alongside the emergence of particulate abatement, monitoring and regulation through each of the four industrial eras.

In this first article we will be examining Industry 1.0 in relation to particulates and how advancements in this era influence modern day power generation and manufacturing.

Industry 1.0

Industry 1.0 (1760-1840) is considered to be the first industrial revolution with the transition to steam and water powered machinery in manufacturing, transforming industries such as agriculture, textiles and mining. The efficiencies made within the steam engine design enabled its use in manufacturing processes (such as Iron production) and developments in rail and shipping saw the expansion

of trade and increased manufacturing output. During this period coal burning became widespread.

Particulates during Industry 1.0

Although combustion processes were not yet able to be used as a source for power generation as today, the increased use of coal in industry had a significant impact on pollution levels. There was little understanding of the existence of fine particles and the associated health implications and little regulations controlling emissions. It has been estimated that by the late 18th century ambient PM levels were in excess of 300mg/m3 in London. During this period there was limited technology for pollution control and regulations (in the UK). The first regulation of emissions from industry would not be enacted until the late 1840’S.

Technological advancements during Industry 1.0

Whilst processes for abating emissions were not in place during the first industrial revolution, advances in science were establishing what would become the technology of the future.

Early Electrostatic Precipitator

concept following Corona discharge

discovery in 1824

The discovery of corona discharge as a method to remove particles from an aerosol was made in 1824 by M Hohlfeld. This lead to the invention of the Electrostatic Precipitator (ESP) by Frederick Gardner Cottrell in 1907, a method widely used today in dust and gas abatement from industrial processes.

The first electrical generator was invented in 1831 by Michael Faraday. Despite its basic design this initial invention set the foundations for the development of electrical power generation as we know it today. The discovery of electromagnetic induction has provided many innovations in Industry including wireless energy transfer which has only begun to be widely used in practical applications during the 21st century.

Particulate Emissions Control in 2019

In 2019 the methods of power generation through combustion have evolved exponentially however the methods developed during Industry 1.0 to power engines (now turbines) through combustion and the pollutants present remain broadly the same. Whilst there is now significant growth in power generation through non fossil fuels, such as EfW and Biomass, there is still estimated to be in excess of 2400 coal fired power stations (30MW and above) currently in operation globally.

Now the most tightly regulated industry for emissions, power generation through combustion employs multiple abatement methods to reduce gas and particulate emissions including flue gas desulphurisation and electrostatic precipitators. Due to the effectiveness of these abatement systems, power stations typically emit the lowest levels of particulate of any industrial process. Whilst significantly more advanced in both efficiency and scale, the basic principles of corona discharge are still central to the technology and the effectiveness of electrostatic precipitators for removing fine particles from a gas stream which is why they are still widely in use over 100 years since their inception.

Industry 4.0 in Particulate Monitoring

Due to the significantly low levels of Particulate Matter (PM) emitted from most modern power stations, continuous particulate monitors are required to measure at extremely low levels with high levels of accuracy and self diagnostic tools to verify the PM measurements.

ProScatter Particulate CEMS Installation

In the PCME ProScatterTM range, ENVEA provide a range of Light Scatter sensors (Forward Scatter and Back Scatter) used globally in power generation processes ideal for measurement after an ESP. Measuring PM emissions, often less then 1mg/m3 ProScatterTM sensors

are networked devices providing single point digital data logging from readings across multiple emission points. This data can be used to control processes ensuring any excessive emissions events are alerted to operators to avoid non-compliance and investigate any process issues.

The sensors include automated self diagnostic checks which provide early warning of both increased dust loadings and changes in particulate type as well as the ability to utilise this data to manage preventive maintenance of both abatement systems and instrumentation. PCME ProScatterTM devices are TUV and MCERTS QAL1 approved with certified measurement ranges as low as 0-7.5mg/m3 providing all the requirements for QAL2 and QAL3 processes as well as being US EPA PS-11 compliant.

With regulators globally requiring increased transparency on emissions data, PCME ProScatterTM devices can be configured to enable direct reporting of online measurement instantaneously to environmental managers and regulators.

ProScatterTMand Backscatter Particulate CEMS

With variations of stack conditions effecting reportable PM measurements, ENVEA also provide a range of flow (velocity) sensors. The STACKFLOW range uses both Pitot and Ultrasonic technology to provide online flow or velocity readings.

These instruments can be networked alongside the PCME ProScatterTM range and readings from both devices calculated to provide normalised continuous PM measurements. Often installed with inbuilt redundancy, ENVEA systems provide a complete environmental and process control solution for measuring PM utilising the digital data analytics, automated self diagnostics and communication methods synonymous with Industry 4.0.

To learn more about the ENVEA range of instruments and further developments towards IIoT, please visit us on Stand 138 at Clean Air Technology Expo taking place on 11-12 September at the NEC, Birmingham.

Click on the links below to read the full article:

How has Industry 1.0 to 4.0 influenced particulate emissions and monitoring_Part 1-Industry 1.0

How has Industry 1.0 to 4.0 influenced particulate emissions and monitoring_Part 2-Industry 2.0

How has Industry 1.0 to 4.0 influenced particuate emissions and monitoring Part 3 Industry 3.0

How has Industry 1.0 to 4.0 influenced particulate emissions and monitoring Part 4 Industry 4.0